In the supermarkets, fragile food can be seen everywhere. It mainly refers to foods that are easily damaged and not easy to maintain integrity during packaging and transportation, such as biscuits, coconut chips, shrimp crisps, dried fruits, puffed food, fried food, etc.

Those products are mainly packaged in bags, cans, jars and boxes.

Wherein, bag packaging includes form bag packaging and premade bag packaging.

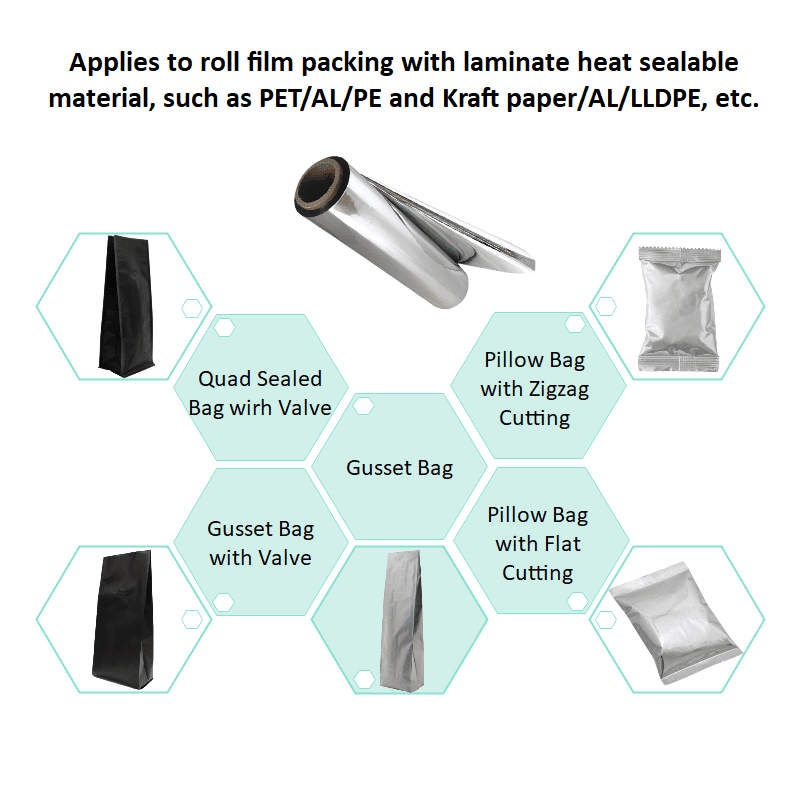

- For pillow bag packaging, the packing machine will form the bags from roll film first, then fill and seal.

- For premade bag packaging, the packing machine could finish filling and sealing.

For fragile food, no matter what kind of bag packaging, nitrogen flushing can effectively reduce damage during transportation and placement.

We could provide the above two types of bag packing machines.

This post is about premade bag packing solution. If you want to know information about back seal bag packaging, please contact us.

Typical premade bag packing machines

Model 116 | Model 146 | Model 109 | |

Flat bag | √ | √ | √ |

Stand-up bag | √ | √ | √ |

Quad sealed bag | √ | √ | √ |

Gusset bag | √ | √ |

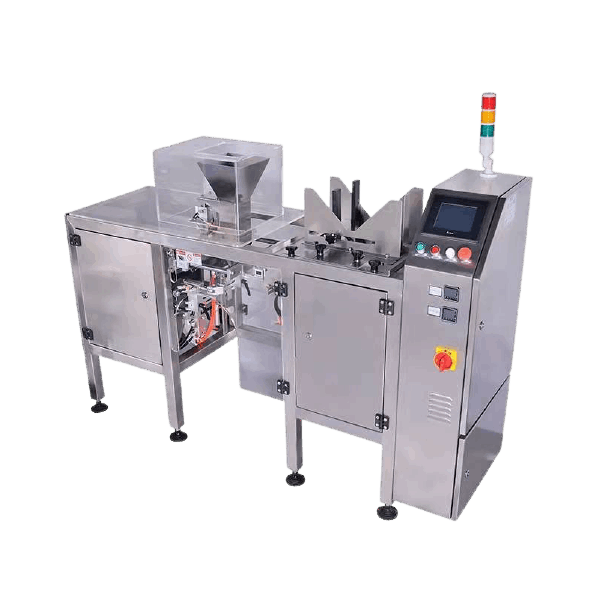

Affordable bag packing machine with great compatibility of bag formats

- Speed: 5~10 bags/min

- Working stations: Single or double stations meet different speed requirements

- Bag compatibility: 10 mins bag formats changeover

- Features: Small footprint; Easy maintenance, Friendly to set-up business

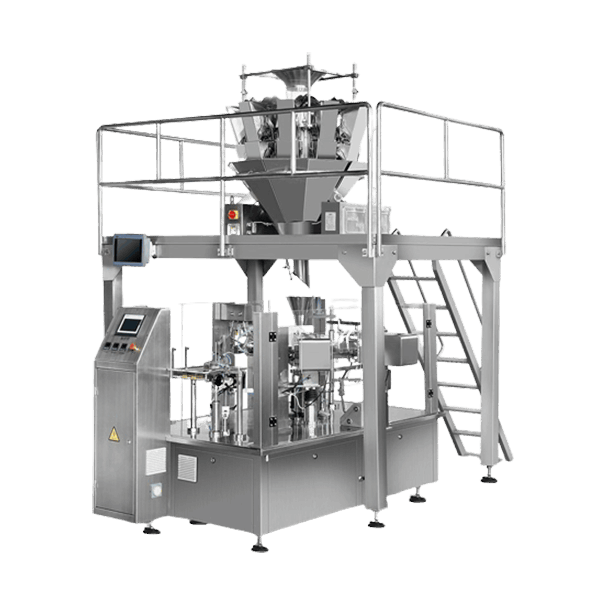

The easiest packaging machine to operate

- Speed: 20~40 bags/min

- Working stations: 8-station design to meet complex packaging requirements

- Bag compatibility: Great compatibility of bag sizes, bag size changeover within 5 mins

- Features: Mechanically driven bag clamps, stable heavy bag packing; Centralized self-lubricating system

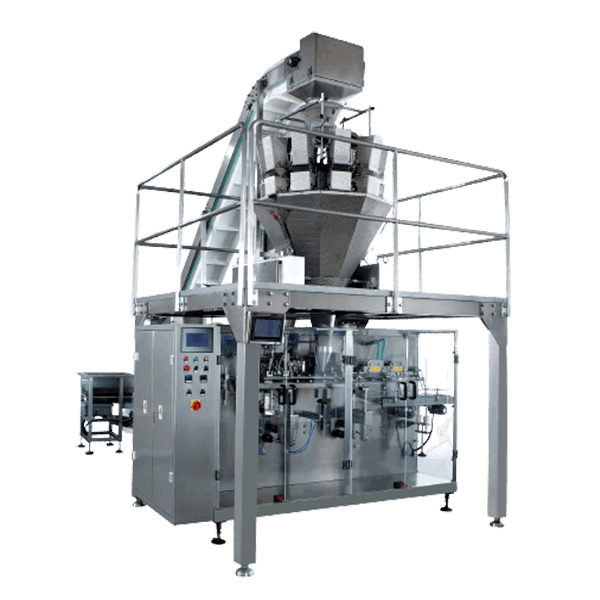

High-speed bag packing machine

- Speed: 40~90 bags/min

- Working stations: Up to 9 stations enable complex and flexible packing process

- Bag Compatibility: Good compatibility of bag formats

- Features: Twice filling for faster filling speed or multiple product filling; Hot sealing & cold sealing, twice sealing for tight sealing

The Dosing Device--Weighers

For the completed packaging system, a packaging machine is not enough, the dosing device is also required.

For granules packing, we have two types of weighers to match different packing machines.

Linear Weigher

Powered by vibration, linear weigher is applicable for weighing free flowing products.

With the limitation of weighing speed, linear weigher usually applies to model 116(linear type). As in the above picture.

Multi-head weigher is applicable for weighing solidity products by way of combination mode, and can be specially customized, such as salad vegetables, sticky products, and fragile products.

Because of the speed, it is usually configured to model 109(rotary type) and model 146(horizontal type).

There is a model customized for fragile products.

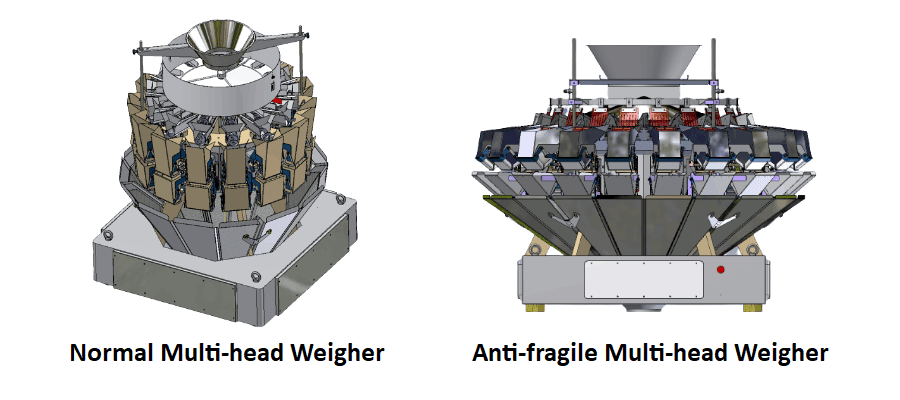

By comparing the pictures, the main differences of anti-fragile multi-head weigher is very obvious.

- Short falling height, to reduce damage of falling.

- The angle design of discharge chute, provides cushioning when food falls.

The above is about the solution to fragile food premade bag packaging.

If you want to know more related content and end-line packaging information, you can contact us.