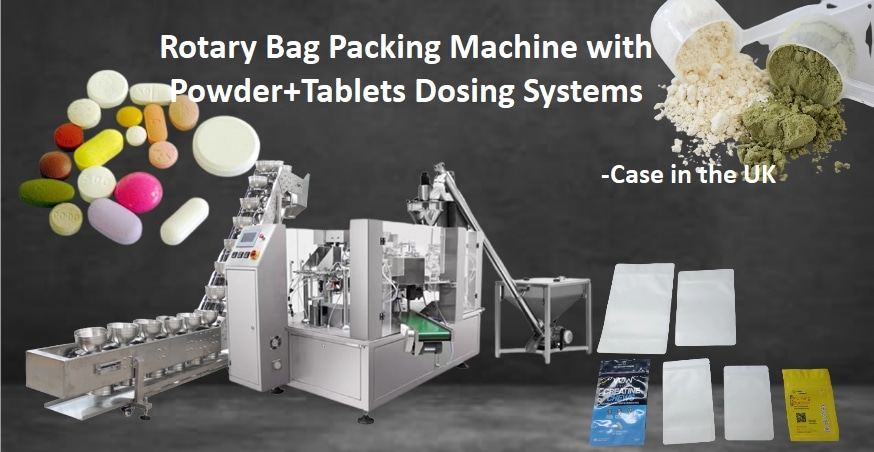

Project Profile

- Project NO. : GPG011

- Country: The United Kingdom

- Product:

Powder: 25~1000g

Tablets: 30~500 tablets - Packing Speed: 25~35 bags/min

- Packing Machine Series: PP109 - Mechanical Type Rotary Premade Pouch Packing Machine

- Configuration:

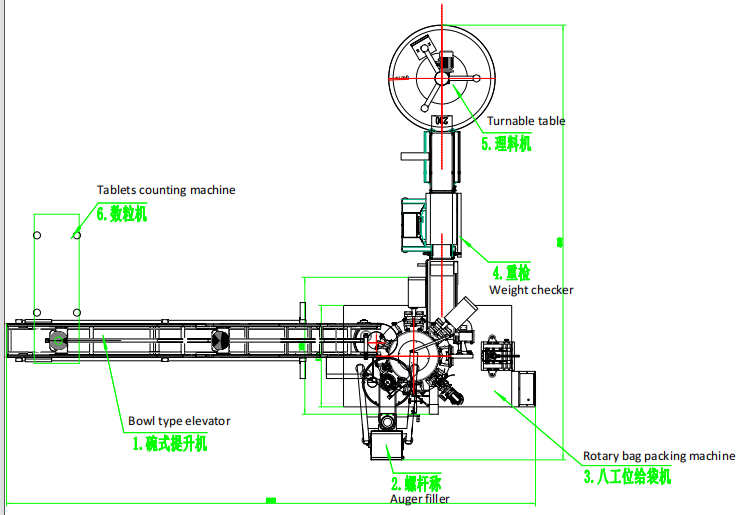

1) Packing Machine: Mechanical rotary bag packing machine

2) Dosing machines: Auger filler + Tablets counting machine

3) Others: Horizontal Screw+Bowl Type Elevator+Dynamic Check Weigher+Turning Table+Dust Vacuum Collection Machine Packaging Format: Stand-up Bag with Zipper

This project is with a UK contract manufacturer in the healthcare industry.

They are committed to the production and packaging of various types of human or pet health care capsules, tablets, supplement powder and other products.

Based on the diversification of products, we provide them with this customized solution -

a rotary packaging machine with two different metering systems.

Two metering systems are used for tablets/capsules counting packaging and supplement powder packaging.

Packaging Processes

Testing Videos Show

HIGHTLIGHTS

For rotary premade bag packing machine

- Two filling systems--Customized two filling stations, no need to move machines for change dosing machines

2. Synchronous bag width adjustment device, flexible bag size changeover in 5 minutes

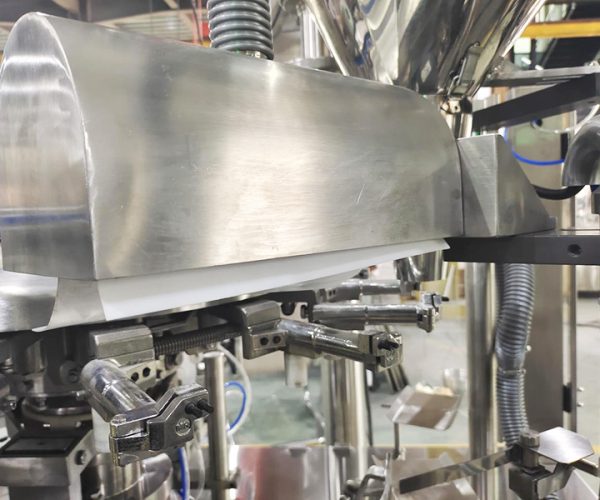

3. Dust remover on the seal area, clean the dust for a tight sealing effect, especially for powder filling

4. Auto lubrication system, easy daily maintenance

5. Upgraded controlling system for remote debugging

6. Configured with cover glass, safety door interlock

For tablets/pills/capsules counting packaging

- Photoelectric counting and filling machine, anti-dust sensor technology, anti-disturbance control system

- Anti-fragile design in the bowl-type elevator, for fragile pills

For powder filling packaging

- Auger Filler Integrated with Horizontal ScrewDetachable horizontal screw, will connect with the production machine/bin, to avoid rapid or large amounts of loading so that the powder density in the hopper is uneven, affecting the filling accuracy

- Dust vacuum collection machine, upgraded machine, lower noises, more efficient, one-key type vibration cleaning

System Layout

If you want to know more details and get your tailored solution, please contact us.