GloexPack is one of the subsidiaries of Gloex, which aims to pre-made bag packing machines and auxiliary configurations, covering food, pharmaceuticals, beverage, cosmetics, daily chemical, and other industries, with more than 15-year experience in the packaging machine manufacturing.

Typical Pre-made Pouch Packing Machine

GloexPack has three typical pre-made bag packing machines. Every machine has its own unique characteristics to meet different packing situations.

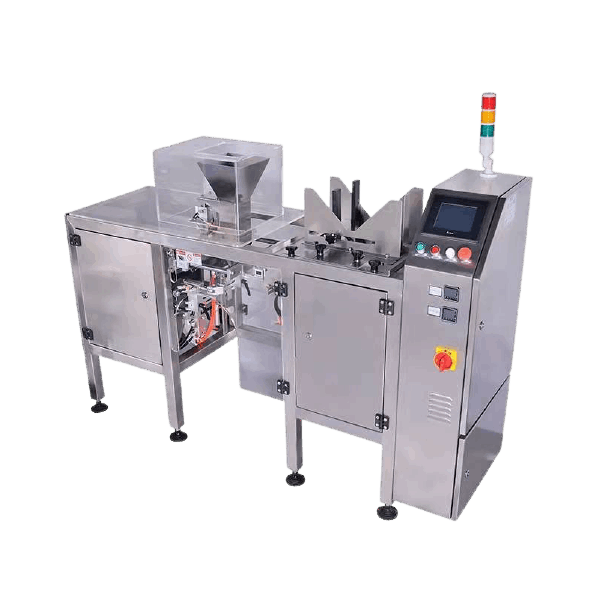

Affordable bag packing machine with great compatibility of bag formats

- Speed: 5~10 bags/min

- Working stations: Single or double stations meet different speed requirements

- Bag compatibility: 10 mins bag formats changeover

- Features: Small footprint; Easy maintenance, Friendly to set-up business

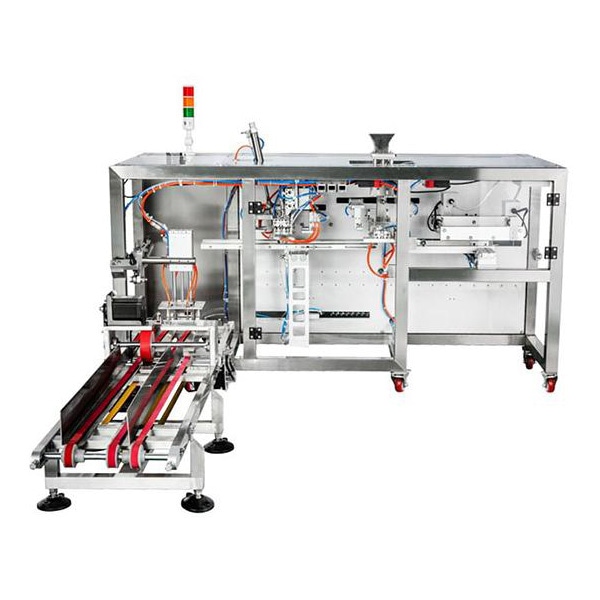

Cost-effective bag packing machine

- Speed: 6~18 bags/min

- Working stations: 4-station design to finish more complex packaging processes than that of model 116 can do

- Bag compatibility: For quad bag or gusset bag, one machine for one bag type

The easiest packaging machine to operate

- Speed: 20~40 bags/min

- Working stations: 8-station design to meet complex packaging requirements

- Bag compatibility: Great compatibility of bag sizes, bag size changeover within 5 mins

- Features: Mechanically driven bag clamps, stable heavy bag packing; Centralized self-lubricating system

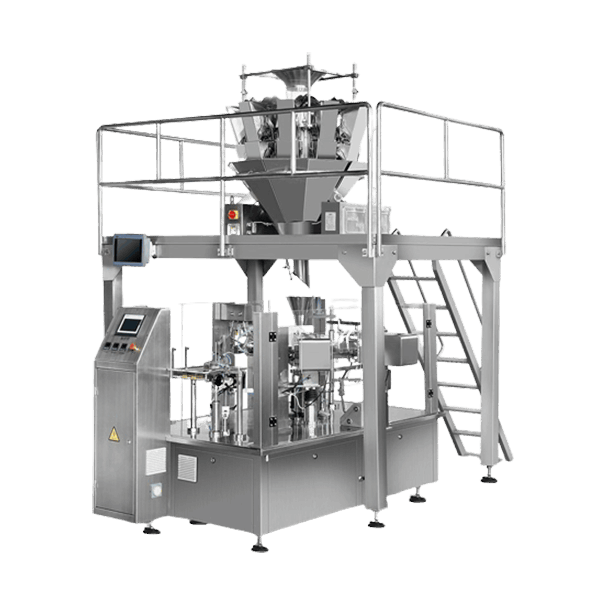

High-speed bag packing machine

- Speed: 40~90 bags/min

- Working stations: Up to 9 stations enable complex and flexible packing process

- Bag Compatibility: Good compatibility of bag formats

- Features: Twice filling for faster filling speed or multiple product filling; Hot sealing & cold sealing, twice sealing for tight sealing

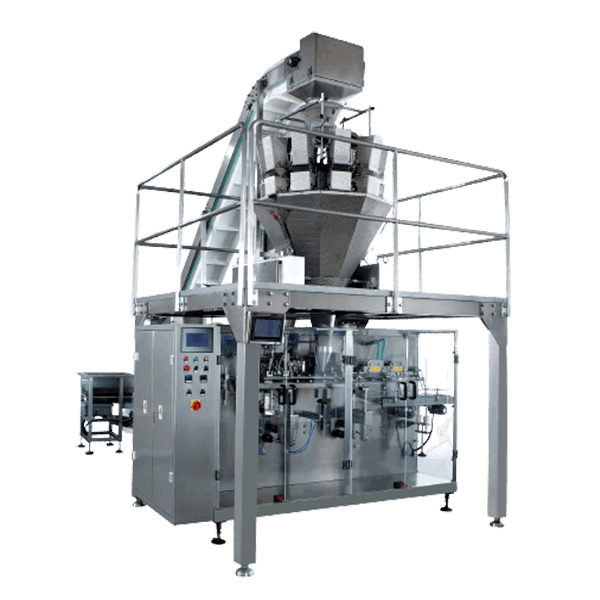

Packaging Systems Display

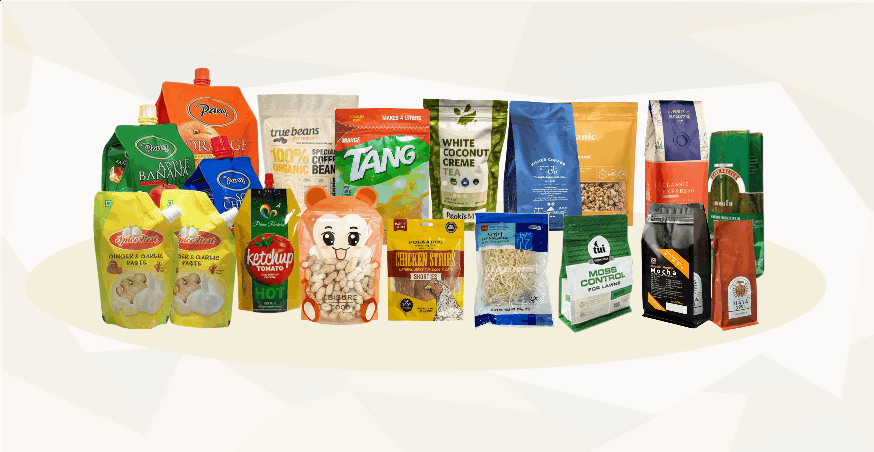

Applicable Pouch Formats

Gusset bags are a special bag type.

In addition to single-station machines(Model 116) that can be compatible, other machine series require specialized machines to complete its packaging individually.

| Flat bag | Stand-up bag | Quad sealed bag | Gusset bag | |

| Model 116 | √ | √ | √ | √ |

| Model 173 | √ | √ | √ | √ |

| Model 146 | √ | √ | √ | √ |

| Model 109 | √ | √ | √ | √ |

Typical Configuration of Product Feastures

With a professional engineering team, GloexPack will offer the customized dosing system to fit your products features.

For Powder Packaging

The standard configuration is screw auger.

For free-flow powder

- Grid: To adjust the speed and frequency of powder agitating.

- Pneumatic driving damper: To prevent powder self-flowing.

For Poor-flow powder

Forcing screw auger: To ensure filling speed through pressure.

For dusty powder

- Pre-sealing jaws:Anit-dust device for filling, to prevent product contamination of sealed areas during filling.

- Dust collection device:On Filling Hopper, to collect the dust during filling.

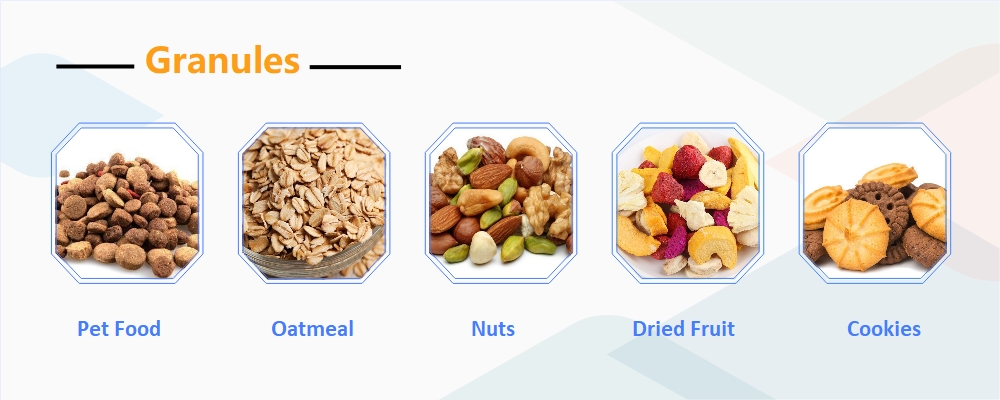

For Granules Packaging

- Vacuuming & Nitrogen flushing device:

To keep products fresh and anti-fragile during transportation.

For Liquid Packaging

- CIP system:

1. Automatic cleaning for the dosing system.

2. Integrate the CIP program on PLC - Drip collection pan:

Receiving the liquid drop, to keep sealing jaw clean. - Air exhausting device for liquid:

Decrease the air in bags, to ensure the beautiful bag shape.

If interested, contact us to optimize your packaging process.