Our Pre-made pouch packaging machines are applicable for various powder products, including various powdered foods, medical powder, condiment powder, chemical raw materials powder, daily chemical products and other powder products.

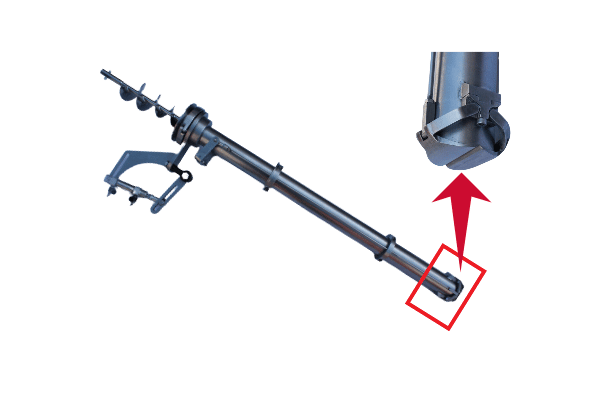

Typical Configuration for Powder Dosing

Servo driven auger is our standard auger dosing configuration. The dosing value is adjustable to a certain range. Compared with stepper motor driven, or Inverter motor driven, our servo auger will have a higher dosing accuracy and could adjust the value by PLC directly.

Typical Configuration to Fit Particular Powder Features

For Fine Flow Powder

- Grid

1. For screw feeder

2. To adjust the speed & frequency of powder agitating

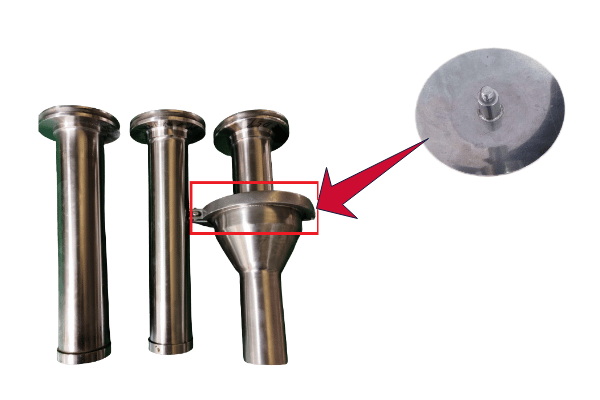

- Centrifugal Plate

1. For auger filler

2. Avoid the self-flowing of powder, to affecting filling accuracy

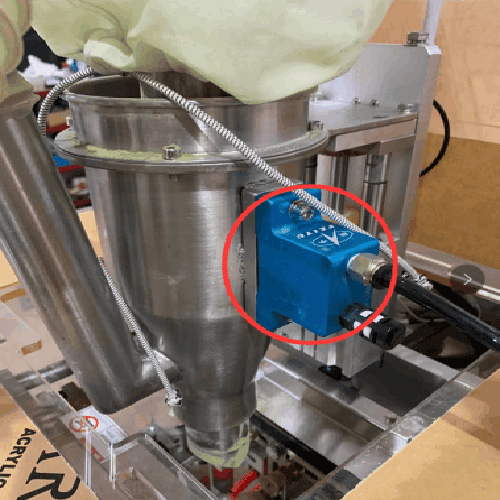

- Pneumatic Driving Damper

Prevent powder self-flowing

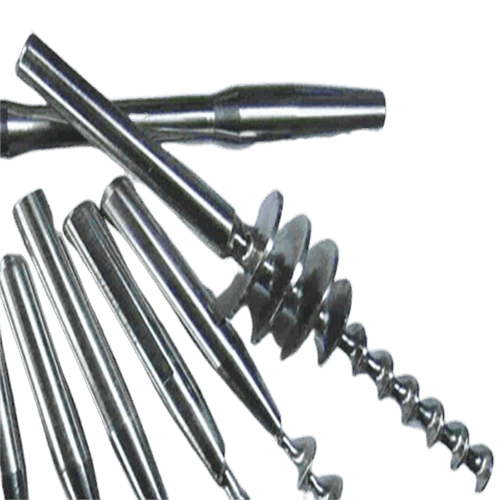

For Sticky Powder

- Forcing Screw Auger

With typical auger design, the push the sticky powder filling with pressure

- Vibration devices

The vibration device is aimed to avoid the thin powder sticking to the inner wall of the hopper.

Typical Anti-dust System

- Dual barrel vacuum cleaner

Separate dust connection and cleaning system for the whole packing process

- Flexible Connection During Filling

Prevent dust during filling

- Dust Collection System on Filling Hopper

For dust collecting while filling, the system includes:

1) The dust collecting fan with air flow adjustable feature

2) The customization of the filling hopper

3) The connecting plastic pipes

Typical Powder Pre-made Bag Packaging Systems

Our three series of pouch packing machines are linear type(Model 116), horizontal type(Model 146) and rotary type(Model 109). Every series has its own application and characteristics.

Model 116 (Linear Pre-made Pouch Packaging Machine)

- Speed: 5~10 bags/min

Model 109 (Rotary Pre-made Pouch Packaging Machine)

- Speed: 20~40 bags/min

Customized for your real project.

Contact us to know more configurations.