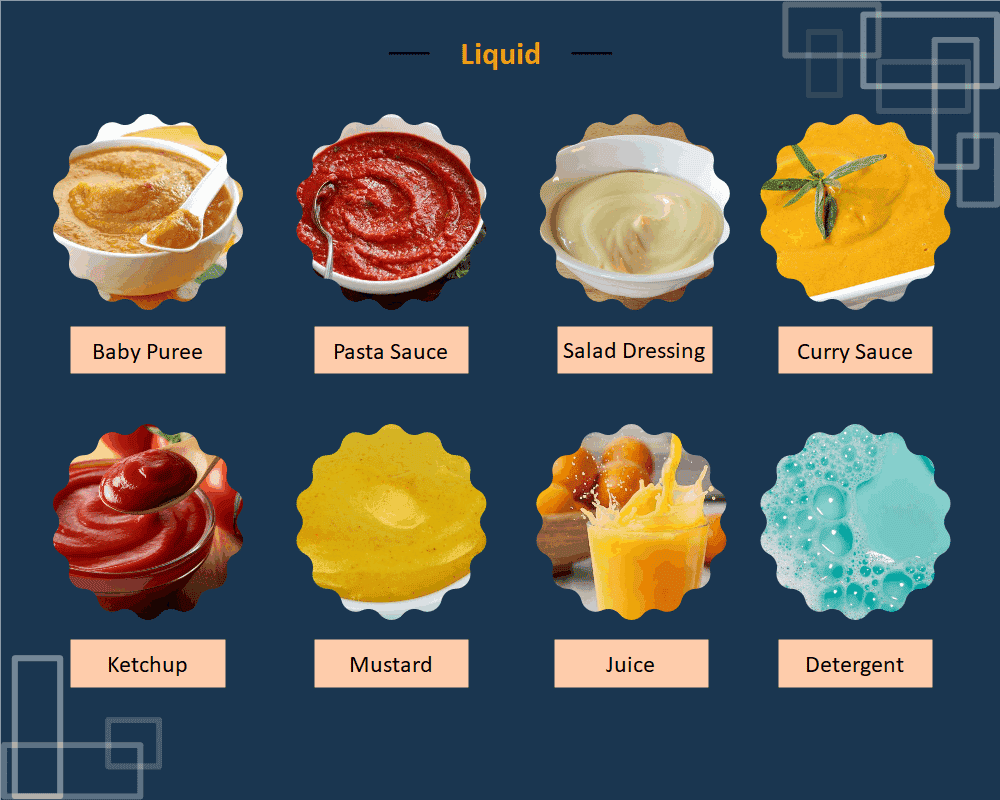

For liquid products, pre-made bag packaging machines are often used in the food industry and the daily chemical industry.

In the food industry, our pre-made pouch packing machines are mainly used for packaging of various sauces and various beverages, such as ketchup, salad dressing, pasta sauce, mayonnaise, mustard, curry sauce, yogurt, baby puree, probiotic beverages and juices, etc.

In the daily chemical industry, our machines are applied to shampoo, liquid detergent, mask material and so on.

Bag Types

Some products are packed in flat bags, stand-up bags, but mostly are packed in spout bag, like straight spout bags and corner spout bags, and irregular shaped bags.

Typical Dosing System

Filling Pumps for your options

For various liquid products with different characteristics, we have four types of pumps to measure them.

Piston Pump

Well fit with the features of most liquid products, this model pump is most popular and widely configured on packing machines.

- For free-flow liquid, like water and other drinks.

- For viscous liquid, like shampoo, salad dressing and yogurt.

- For sauces with small granules, like pasta sauces, baby puree, and curry sauce.

Gravity Pump

This pump is particularly applid for free-flow liquid, like water.

Peristaltic Pump

This pump is also for free-flow liquid. With pipes connecting, it is easy to clean and change over for different products packing. But it's more suitable for small volume dosing.

Ceramic Pump

This pump is advantageous in bearing strict product features, such as: Highly wear-resistant, temperature-resistant, biological-and chemical-resistant and low thermal expansion of the parts. But it is not suitable for highly viscous products.

Auxiliary configurations on Pumps

During dosing, there are 2 main headache problems:

- Dripping with free-flow liquid filling

- Pulling thread with viscous liquid

To solve the problems and ensure the packing performance, we have below configurations for your reference.

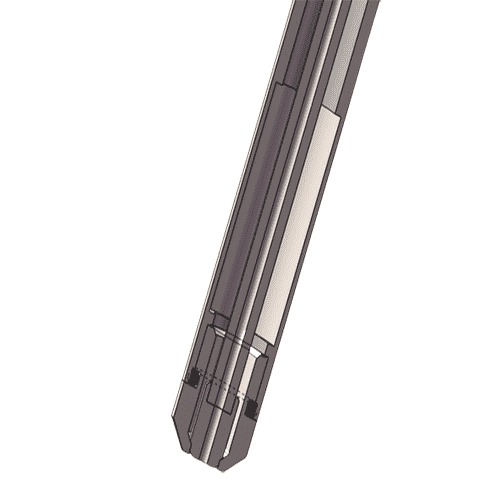

Anti-drop Nozzle

Preventing liquid flowing, to ensure the accuracy of filling and keep the outside of bag clean.

Anti Pulling Thread Device

It is specially designed for viscous liquid. Through air blowing, to break the thread pulling of filling hopper.

Double Jacket Heat Insulation Hopper

It ensures a suitable filling temperature, to increase the fluidity of the liquid, for better filling accuracy, like chocolate.

Main Packing Machine recommendation

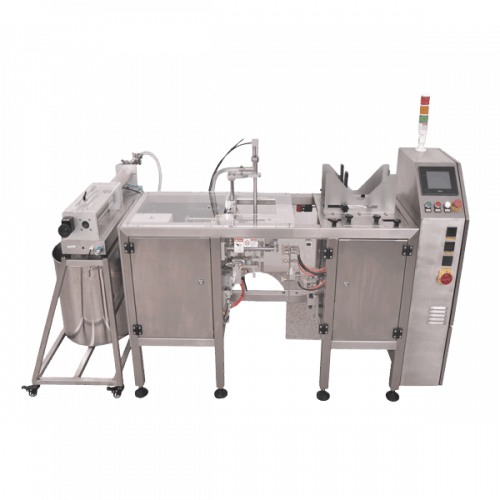

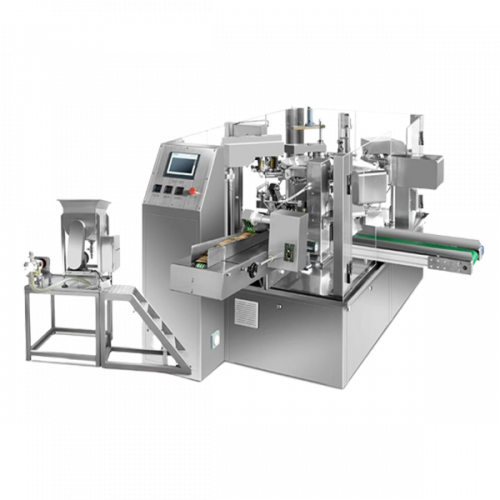

Model 146 (Horizontal Pre-made Pouch Packaging Machine)

- Speed: 40~90 bags/min

Customized for your real project.

Contact us to know more Details.