What sauce do you like to add to pasta? Black pepper sauce, ketchup, meat pasta, or anything else?

When you eat salads, burgers, and bread, do you add salad dressing, mayonnaise, or tartar sauce?

Do you add ketchup to your potato fries at a fast food restaurant?

Have you ever cooked with bean paste or soy sauce?

In addition, there are common barbecue sauces, chocolate syrup, chili sauce, nut butter, mushroom sauce, jam, and so on. What else sauce do you know?

Sauce is a very important condiment in our diet.

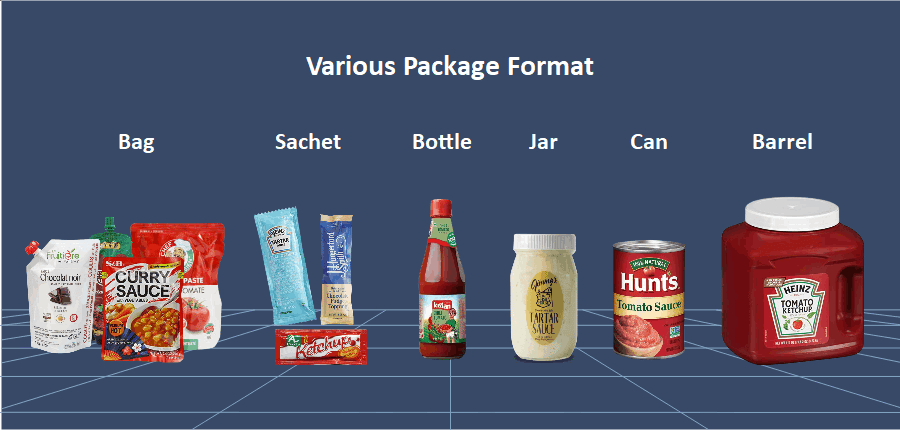

Typical Packaging Formats

They also come in a variety of packaging formats, like flat bag, stand-up bag, corner spout bag, straight spout bag, sachet&stick, bottle, jar, can, barrel, and other special packages.

Gloex can help you do all of the packaging types in the above picture.

However, this article only talks about the solution for bag packaging.

If your packaging type belongs to others, please contact us directly and we will introduce the suitable machine for you.

Requirements on Sauces Packaging

Since there are so many types of sauces, each one has different textures and characteristics.

For different sauces, there are different requirements.We will evaluate their textures and characteristics if need any additional accessories to achieve a stable dosing performance.

How to show us the characteristics of the sauce? Better to take a video like the test in the video below.

Temperature controlling

At room temperature, some sauces have very poor fluidity, such as chocolate syrup, honey, etc.

In this situation, we will recommend configuring the Double Jacket Heat Insulation Hopper. It is necessary to make sure there is a suitable filling temperature to increase fluidity.

Anti-dripping

For sauces with good or free-flow fluidity.

Preventing dripping after filling can prevent damage of the material to the internal structure of the machine and contamination on the outside of the package.

Meanwhile, it could ensure the best filling accuracy.

Anti-thead

For viscous liquid

Breaking the vicious thread after filling through air blowing, to avoid contamination of sealing tool.

Machine Construction

The surface and product touching parts are made of Stainless Steel 304, which is compliant with food industry standards.

Above are the main requirements. If you would like to know more, contact us now.

Typical Bag Packaging Machines

Every premade bag packing machine has its different applicable ranges and characteristics, as follows.

Model 116 | Model 146 | Model 109 | Model 133 | |

Flat bag | √ | √ | √ | |

Stand-up bag | √ | √ | √ | |

Corner spout bag | √ | √ | √ | √ |

Straight spout bag | √ | √ | √ | √ |

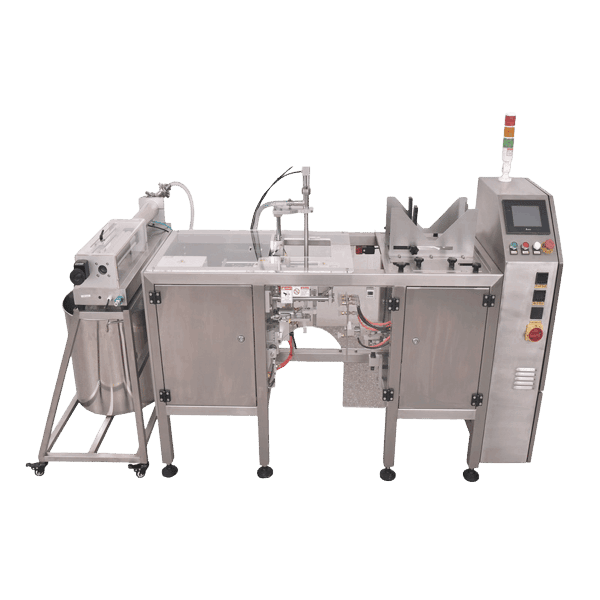

Best Bag Packing Machine for Small-Scale Production

- Speed: 5-10 bags/min

- Features:

1. Small footprint

2. Bag changeover for 10 mins

3. The best effect of vacuuming and Nitrogen flushing - Bag compatibility:

1. For all bag types

2. Filling way for corner spout bag: Via the top of bag

3. Filling way for straight spout bag: Via the bottom of bag

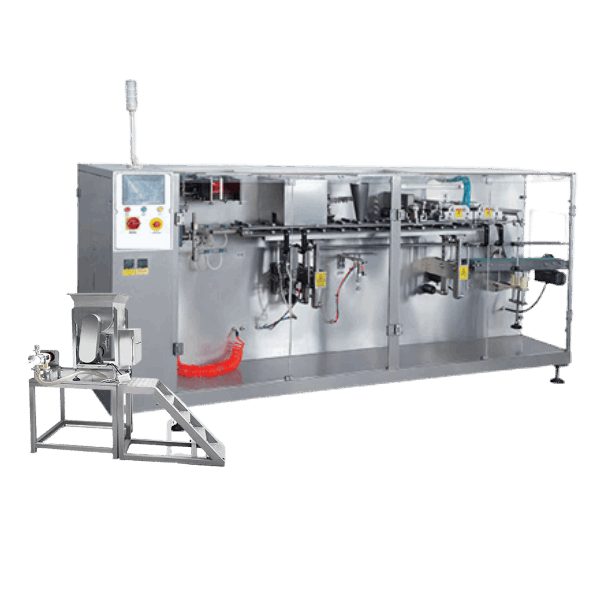

High-Speed Bag Packing Machine with Welding Spout

- Speed: 40-90 bags/min

- Features:

1. Welding spout

2. Twice fillings for faster filling speed or multiple product filling

3. Twice sealings for tight sealing, hot sealing & cold sealing - Bag compatibility:

1. For all bag types

2. Filling way for corner and straight spout bag:

Firstly, filling the materials into the bag via the top of the bag, then weld the spout

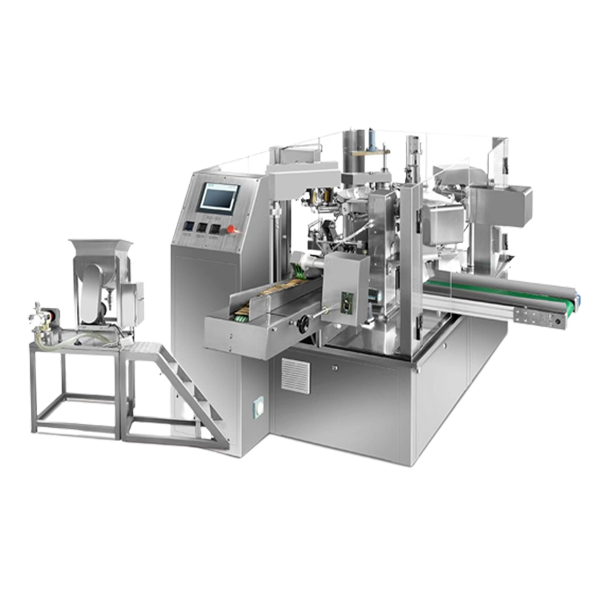

Fastest Changeover Bag Packing Machine

- Speed: 20-40 bags/min

- Features:

1. Heavy-duty design, stable working

2. Bag size changeover for 5 mins, easy to maintenance - Bag compatibility:

1. For all bag types

2. Filling way for corner spout bag: Via the top of bag

3. Filling way for straight spout bag: Via the bottom of bag

Professional Spout Bag Packing Machine

- Speed: 8~12 bags/min/head, depending on the number of heads

- Features:

1. Auto cap sorting, pre-capping, and capping

2. Heads number: Customized - Bag compatibility:

1. For corner spout bag&straight spout bag

2. Filling way: Via the spout(nozzle)

For the spout bag, it requires the nozzle with 3 layers.

If you want to know know about our machines, please contact us through the right list.

Tell us your project details, and get your customized solution.

Our engineers will give you the optimal solution within your budget.

If you don't know what information to provide, you can refer to this article: KNOW BEFORE ORDERING PACKING MACHINE

What are our customers saying? Click Reviews, and you will learn GloexPack more. Hurry up to send your inquiry to get your customized solution!(via the right form)